Insights on semiconductor supply news: what you need to know

Insights on semiconductor supply news reveal that diversifying suppliers, improving inventory management, and investing in technology are crucial strategies for businesses to navigate ongoing supply chain challenges.

Insights on semiconductor supply news can shed light on significant market dynamics affecting industries worldwide. If you’ve noticed disruptions in the tech world, it’s time to dive deeper into what’s behind these changes.

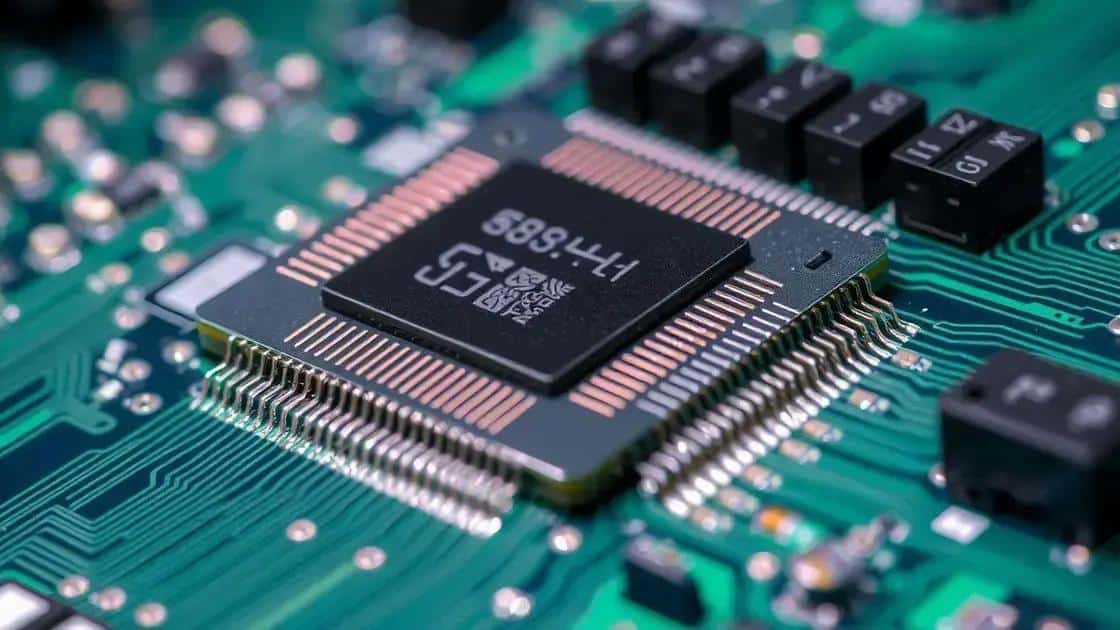

Current state of the semiconductor supply chain

The current state of the semiconductor supply chain is essential for understanding how various industries function. The semiconductor industry plays a vital role in the production of many high-tech devices we use daily. Recent events have shed light on how delicate this supply chain can be.

Recent Disruptions

Several factors have contributed to disruptions in the semiconductor supply chain. Natural disasters, geopolitical tensions, and increased demand have all impacted production. These elements create challenges for manufacturers and consumers alike, leading to delays in product availability.

Key Components Affected

Many components are part of the broader semiconductor supply chain:

- Wafer production: The initial stage, where silicon wafers are created, is critical.

- Packaging and testing: After production, chips need careful packaging and testing to ensure functionality.

- Distribution: Logistics play a significant role in the timely delivery of chips to manufacturers.

Monitoring these stages helps understand the overall health of the supply chain.

Furthermore, the shift toward electric vehicles and renewable energy technologies is increasing demand for semiconductors. Businesses must adapt quickly to stay competitive in this evolving market. The challenges often lead to increased prices and longer wait times.

Despite the setbacks, various companies are investing in expanding production capacity. For instance, some manufacturers are considering new factory locations to counteract supply chain vulnerabilities.

Impact of global events on semiconductor availability

The impact of global events on semiconductor availability is significant and often unpredictable. Recent disruptions have taught industries that the semiconductor supply chain is sensitive to many external factors.

Economic Factors

Economic fluctuations can have a profound effect on semiconductor supply. When the global economy booms, demand for electronic devices rises, resulting in a strain on semiconductor manufacturers. Conversely, during economic downturns, production can slow down, leading to shortages.

Geopolitical Tensions

Geopolitical events also play a crucial role. Issues between countries can disrupt manufacturing and distribution. For example, trade disputes may cause tariffs, increasing the cost of components and making it harder to secure necessary materials.

- Sourcing difficulties: Companies may find it challenging to get raw materials.

- Transportation delays: Conflicts can hinder shipping routes, impacting delivery times.

- Investment shifts: Geopolitical risks may lead businesses to rethink investments in certain regions.

These events underline how interconnected the semiconductor industry is with the global landscape. Natural disasters, such as earthquakes and floods, can halt production at key facilities. After such events, manufacturers struggle to meet the rising demand.

COVID-19 has also had a lasting impact. The pandemic caused factory shutdowns that slowed down production. Even now, many companies are still catching up. As the world shifts toward digital solutions and remote work, demand for semiconductors has surged, further stretching resources.

Companies must create contingency plans to navigate these uncertainties. Adapting to ever-changing global conditions can help businesses maintain stability in their operations. Ultimately, understanding these impacts will help industries make informed decisions about their tech investments.

Future trends in semiconductor production

The future trends in semiconductor production will significantly shape technology industries around the world. As demand for electronics rises, manufacturers are looking for ways to innovate and improve production efficiency.

Advancements in Technology

One major trend is the development of new manufacturing technologies. Companies are investing in advanced techniques such as 3D chip stacking and smaller process nodes. These innovations allow for more powerful and efficient chips, which means better performance in devices.

Increased Automation

Automation is another key aspect of the future. By utilizing robots and artificial intelligence, manufacturers can reduce human error and speed up production times. Automation not only enhances efficiency but also helps in maintaining quality control.

- Robotic assembly: Machines will take on tasks previously done by humans.

- AI-driven quality checks: AI can monitor outputs to ensure standards are met.

- Predictive maintenance: Automation can help predict breakdowns before they happen.

As technologies evolve, the semiconductor industry is also focusing on sustainability. Companies are increasingly aware of their environmental impact and are pursuing greener practices. This includes the use of recyclable materials and reducing waste during production.

Alongside sustainability, the shift towards localized production is gaining traction. Many regions are looking to establish semiconductor fabs closer to home. This shift aims to reduce dependency on global supply chains and can help mitigate risks associated with geopolitical tensions.

Surging demand for electric vehicles and renewable energy solutions is also influencing semiconductor production. As these sectors grow, the need for specialty semiconductors tailored to automotive and energy applications is becoming critical. Manufacturers will need to adapt quickly to meet these changing demands.

Strategies for businesses to navigate supply challenges

Businesses must employ effective strategies to navigate supply challenges in the semiconductor market. As the global landscape shifts, adapting to these changes can be vital for success.

Diverse Sourcing

One of the most impactful strategies is diversifying suppliers. Relying on a single source for semiconductors can lead to potential disruptions. By establishing relationships with multiple suppliers, companies can mitigate risks related to shortages or unforeseen events.

Inventory Management

An effective inventory management system is essential. Businesses should implement just-in-time (JIT) practices alongside safety stock strategies. This balance helps in maintaining enough inventory without overstocking.

- Regular audits: Conducting regular stock audits can help identify trends and needs.

- Demand forecasting: Using data analytics for precise demand forecasting allows better preparation for changes in orders.

- Flexibility: Having flexible agreements with suppliers aids in quicker adjustments to production needs.

Moreover, companies must invest in technology to improve visibility across the supply chain. Advanced tracking systems enable businesses to monitor shipments and assess potential delays before they impact operations. This proactive approach helps in making informed decisions about adjustments.

Collaboration is another key strategy. By working closely with suppliers, companies can share insights and expectations. This communication builds trust and creates a stronger partnership. It also fosters innovation, driving improvements in processes that benefit both parties.

Investing in local production facilities is an increasingly popular trend. By establishing operations closer to end-users, businesses can reduce lead times and costs associated with international shipping. Localized production can also respond faster to changes in market demands.

Ultimately, companies must remain agile. The semiconductor market is rapidly evolving, and being able to adapt quickly is essential for staying competitive. Implementing these strategies will enable businesses to navigate supply challenges effectively and thrive in a dynamic landscape.

FAQ – Frequently Asked Questions about Semiconductor Supply Challenges

What are the main challenges in the semiconductor supply chain?

The main challenges include supplier shortages, transportation delays, and economic fluctuations that can disrupt production.

How can diversifying suppliers help my business?

Diversifying suppliers reduces risk by ensuring that if one source fails, you have alternatives to maintain your production.

Why is effective inventory management important?

Effective inventory management helps balance supply and demand, preventing overstocking and shortages while optimizing costs.

What role does technology play in supply chain visibility?

Technology enhances supply chain visibility through tracking systems, allowing businesses to monitor shipments and anticipate delays.